HomeHolographic Films

HOLOGRAPHIC FILMS

AESTHETIC & SECURITY PACKAGING LAMINATION FILMS

Holofilm effectively caters to all your holographic film needs, delivering products tailored to your specific requirements. Our holographic films are widely trusted by laminators, converters, manufacturers, and suppliers globally, showcasing their exceptional quality.

To enhance brand appeal and capture customer attention in competitive retail spaces, Holofilm's advanced holographic film designs provide a range of visually striking effects for packaging.

Holofilm's customized holographic films are developed to safeguard authentic products and verify their genuineness. These solutions are extensively utilized by brand owners and manufacturers to combat counterfeiting and protect their brand reputation.

Holofilm delivers seamless packaging films suitable for premium packaging and decorative label purposes.

To ensure extended shelf life for packaged products, our holographic packaging films are crafted from top-quality raw materials, offering excellent protection against moisture and oxygen while preventing oxidation.

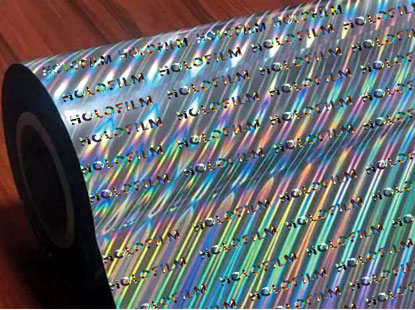

CUSTOMIZED METALIZED HOLOGRAPHIC FILMS

Customized metallized holographic films are tailored for specific branding and security needs. Created by depositing a thin metal layer onto holographic film, they offer durability and stunning, multi-dimensional effects. These versatile films can be customized with unique patterns, logos, and security features, making them ideal for packaging, labels, and promotional materials. They help businesses enhance brand presence, prevent counterfeiting, and stand out in a competitive market.

- Customized Design

- Silver Metalized

- PET - Polyester Film

- 12 Micron Thickness

- Upto 1.6 Meter Width

- 3 Inch or 6 Inch Core ID

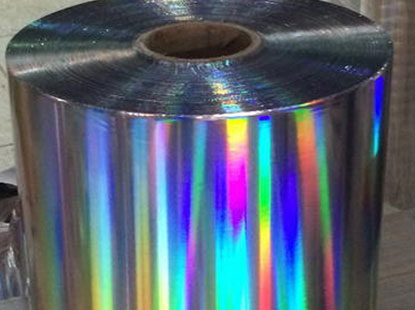

GENERIC METALIZED HOLOGRAPHIC FILMS

Generic metallized holographic films are versatile and striking, perfect for packaging, branding, and decorative needs. Featuring a metallic layer with holographic patterns, they provide an attractive, shimmering effect. Suitable for various industries, including cosmetics, retail, and food packaging, these films enhance product aesthetics and offer durability. Their compatibility with printing and lamination makes them a practical and cost-effective option for elevating product presentation.

- Generic Design

- Silver Metalized

- PET - Polyester Film

- 12 Micron Thickness

- Upto 1.6 Meter Width

- 3 Inch or 6 Inch Core ID

CUSTOMIZED TRANSPARENT HOLOGRAPHIC FILMS

Customized transparent holographic films enhance product presentation and brand identity with unique, eye-catching patterns. These see-through films allow the original design to shine through, complemented by shimmering effects. Commonly used in cosmetics, pharmaceuticals, and luxury goods, they offer visual appeal and protective features, such as authenticity verification. By incorporating logos, patterns, or custom text, they blend functionality and elegance to elevate any product.

- Customized Design

- Transparent

- PET - Polyester Film

- 12 Micron Thickness

- Upto 1.6 Meter Width

- 3 Inch or 6 Inch Core ID

GENERIC DESIGN TRANSPARENT HOLOGRAPHIC FILMS

Generic design transparent holographic films offer visual appeal and security with a clear base and intricate holographic patterns. Ideal for packaging, labels, and decorative uses, they add sophistication and intrigue without hiding the content. These films enhance product appeal with shimmering patterns and provide counterfeit protection. Perfect for businesses aiming to elevate their packaging and branding with modern elegance and security.

- Generic Design

- Transparent

- PET - Polyester Film

- 12 Micron Thickness

- Upto 1.6 Meter Width

- 3 Inch or 6 Inch Core ID

CUSTOMIZED COLOUR HOLOGRAPHIC FILMS

Colorful Mylar holographic films with customized designs enhance product visibility and branding. Built on a durable Mylar base, these films showcase unique holographic effects in vivid colors. Widely used in packaging, textiles, and promotions, they create a distinctive appearance and offer anti-counterfeit features, adding security to their visual appeal. These adaptable films are suitable for various applications, providing a balance of durability, functionality, and style to help products stand out.

- Customized Design

- Gold, Red, Blue, Turquoise & More

- PET - Polyester Film

- 12 Micron Thickness

- Upto 1.6 Meter Width

- 3 Inch or 6 Inch Core ID

GENERIC DESIGN COLOUR HOLOGRAPHIC FILMS

Mylar or color holographic films offer dynamic visual appeal and improved security. Their vibrant color transitions and shimmering patterns make them suitable for various surfaces while keeping content visible. Commonly used in packaging, labels, and decorative applications, they add elegance and charm. These films also provide anti-counterfeit properties, making them essential for brands aiming to protect their products while attracting attention with striking designs.

- Generic Design

- Gold, Red, Blue, Turquoise & More

- PET - Polyester Film

- 12 Micron Thickness

- Upto 1.6 Meter Width

- 3 Inch or 6 Inch Core ID

SEAMLESS HOLOGRAPHIC FILMS

Seamless holographic films are cutting-edge technology featuring continuous holographic patterns without visible seams or breaks. These films are ideal for high-end packaging, labels, and decorative applications, providing a smooth and premium appearance. They enhance product appeal with captivating, flawless designs that attract consumer attention. Additionally, these films offer security benefits, making it difficult for counterfeiters to replicate. Seamless holographic films are a great choice for brands aiming to elevate their product presentation while ensuring authenticity and standing out in competitive markets.

- Generic Design

- Silver Metalized

- PET - Polyester Film

- 12 Micron Thickness

- Upto 1.6 Meter Width

- 3 Inch or 6 Inch Core ID

INTERESTED IN HOLOGRAPHIC FILMS

CONTACT US

A UNIT OF BLUE CAP VENTURES

- 225, 1st Floor, Raghuleela Arcade, Sector 30A, Near Vashi Railway Station, Vashi, Navi Mumbai 400703, Maharashtra, INDIA.

- +91- 8928 18 1178

- sales@holofilm.in

BUSINESS HOURS

- Mon - Sat : 10 AM to 6 PM IST - (Sunday Closed)

FOLLOW US

FAQ

COMMONLY ASKED QUESTIONS ABOUT HOLOGRAPHIC FILMS ?

What are holographic films?

How do holographic films work?

What is the basic structure of a holographic film?

Are holographic films the same as rainbow films?

What are the different types of holographic films available?

What is a holographic polyester film?

What is a holographic BOPP film?

What are the key properties of a good quality holographic film?

Can holographic films be customized?

What is the typical thickness range for holographic films?

Are holographic films environmentally friendly?

Are holographic films recyclable?

What is the shelf life of holographic films?

How should I store unused holographic film rolls?

What is the difference between a holographic film and a holographic sticker?

Can holographic films be used for non-commercial or artistic purposes?

Do you provide holographic film samples before bulk ordering?

What is the minimum order quantity (MOQ) for holographic films?

What are the primary applications of holographic films?

How are holographic films used in packaging?

Which product packages commonly use holographic films?

Can holographic films be used for food packaging?

Are holographic films FDA compliant for direct food contact?

How are holographic films used for brand protection and anti-counterfeiting?

What makes holographic films a good security feature?

Can holographic films be used on pharmaceutical packaging?

How are holographic films used in labels?

Can holographic films be used for gift wrapping?

How are holographic films used in the printing industry?

Can you print on holographic films?

Is flexographic printing suitable for holographic films?

What type of printing is best for holographic films?

Can you use offset printing on holographic films?

Is rotogravure printing suitable for holographic films?

What are the challenges of printing on a holographic surface?

Do I need special inks for printing on holographic films?

Should I use transparent or opaque inks on holographic films?

How do I achieve the best print results on holographic film?

Can the holographic pattern be embossed and printed in one pass?

Can holographic films be laminated?

What types of laminates are compatible with holographic films?

Can holographic films be metallized?

What is the difference between transparent, semi-transparent, and opaque metallized holographic films?

Can holographic films be coated?

Can holographic films be corona or flame treated?

Can holographic films be pouched?

What is the maximum web width of holographic film you can offer?

Do you offer slitting and rewinding of holographic films?

What is the tensile strength of holographic films?

What is the elongation at break of holographic films?

What is the typical haze value of a holographic film?

What is the gloss level of holographic films?

What is the oxygen transmission rate (OTR) of holographic films?

What is the water vapor transmission rate (WVTR) of holographic films?

Are holographic films moisture-resistant?

Are holographic films chemical-resistant?

What is the temperature range for storing and using holographic films?

How does temperature affect the performance of holographic films?

Are holographic films dimensionally stable?

What is the shrinkage percentage of holographic films?

What is the coefficient of friction (COF) of holographic films?

Why is COF important for packaging machinery?

What is the surface energy of holographic films?

How does the base substrate (PET, BOPP, etc.) affect the film's properties?

What are the optical density values for different metallization levels?

How is the brightness and diffraction efficiency of a hologram measured?

How are holographic films applied to a substrate?

What is holographic thermal lamination film?

What is holographic wet lamination film?

What is the difference between thermal and wet lamination for holographic films?

What types of adhesives are used in holographic lamination films?

How do I apply holographic film using a laminating machine?

What is the recommended temperature for thermal lamination holographic film?

What is the recommended speed for lamination of holographic films?

How do I avoid wrinkles during holographic film lamination?

How do I avoid bubbles during hologram film lamination?

What substrate preparation is needed before lamination of holographic film?

How do I achieve a permanent bond with holographic lamination film?

How do holographic films prevent counterfeiting?

What is the difference between a generic and a custom security holographic film?

Can you create a custom holographic master for my brand?

What is your supply capacity of holographic films?

Do you export your holographic films globally?

What is the lead time for a standard holographic films order?

What is the lead time for a custom holographic films ?

How is the pricing for holographic films calculated?

What are the payment terms you offer?

What is the cost of creating a custom master shim for holographic films?

Who owns the rights to the custom master shim?

What packaging do you use for shipping film rolls?

What is your policy on product quality complaints?

Do you provide technical support?

Why is the holographic effect weak or dull?

Why is the holographic film cracking or flaking after application?

Why is the ink not adhering to the holographic film?

Why is the holographic pattern getting damaged during rewinding?

Why is my holographic film jamming the packaging machine?

The holographic film is curling. How can I prevent this?

Why does the holographic film have streaks or lines?

Why is the metallization rubbing off?

The laminated holographic film is peeling at the edges. Why?

The film keeps breaking on my converting machine. Why?

The holographic films looks different under artificial light vs. sunlight. Why?

Do you have an in-house design team for hologram origination?

What file format do you require for creating a custom holographic film?

Do you provide Certificates of Analysis (CoA) with holographic film shipments?

How do you handle customs and import duties for international orders of holographic films?

Do you have any affiliated partners for printing or converting?

What are nano-embossed holographic films?

How are holographic films used in brand transformation?

How does humidity affect the converting of holographic films?

Do you conduct wear and abrasion testing on your holographic films?

What are the benefits of holographic PET over BOPP?

What is the typical roll diameter and length you supply?

Widely Recognized Holographic Films Categories & Tags

Clear Holographic Films Cold Lamination Holographic Films Colour Holographic Films Cracked Ice Holographic Films Customized Colour Holographic Films Customized Holographic Films Customized Holographic Films Manufacturer Customized Holographic Films Supplier Customized Holographic Lamination Films Customized Holographic Packaging Films Customized Metallized Holographic Films Customized Transparent Holographic Films Decorative Holographic Films Generic Holographic Films Gold Holographic Films Holographic Clear Films Holographic Cold Lamination Films Holographic Colour Films Holographic Customized Films Holographic Decorative Films Holographic Films Holographic Films for Cosmetic Industry Holographic Films for Flexible Packaging Companies Holographic Films for Flexible Pouch Holographic Films for Folding Carton Industry Holographic Films for Food Packaging Holographic Films Manufacturers Holographic Films Supplier Holographic Gold Films Holographic Lamination Films Holographic Metallized Films Holographic Mylar Films Holographic Packaging Films Holographic Polyester Films Holographic Rainbow Films Holographic Seamless Films Holographic Security Films Holographic Soft Embossed Films Holographic Transparent Films Holographic Wide Web Films Lamination Holographic Films Metallized Holographic Films Mylar Holographic Films Packaging Holographic Films Pillar of Light Holographic Films Polyester Holographic Films Rainbow Holographic Films Seamless Holographic Films Security Holographic Films Soft Embossed Holographic Films Transparent Holographic Films Wide Web Holographic Films

Major Businesses, Organizations, and Brands Leveraging Holographic Films Across Key Cities

New York City | Los Angeles | Chicago | Houston | Phoenix | Philadelphia | San Antonio | San Diego | Dallas | San Jose | Toronto | Montreal | Calgary | Ottawa | Mexico City | Guadalajara | Monterrey | Puebla | León | São Paulo | Rio de Janeiro | Brasília | Salvador | Fortaleza | Belo Horizonte | Manaus | Curitiba | Recife | Porto Alegre | Belém | Buenos Aires | Córdoba | Rosario | Lima | Bogotá | Medellín | Cali | Santiago | Quito | Guayaquil | London | Birmingham | Manchester | Glasgow | Paris | Marseille | Lyon | Toulouse | Nice | Berlin | Hamburg | Munich | Cologne | Frankfurt | Warsaw | Kraków | Madrid | Barcelona | Valencia | Seville | Rome | Milan | Naples | Lisbon | Porto | Vienna | Budapest | Prague | Bucharest | Sofia | Zurich | Stockholm | Oslo | Copenhagen | Istanbul | Ankara | Izmir | Bursa | Gaziantep | Riyadh | Jeddah | Mecca | Dammam | Doha | Kuwait City | Muscat | Amman | Lagos | Cairo | Alexandria | Giza | Kinshasa | Johannesburg | Cape Town | Durban | Nairobi | Addis Ababa | Dar es Salaam | Accra | Abidjan | Dakar | Casablanca | Algiers | Tunis | Khartoum | Sydney | Melbourne | Brisbane | Perth | Auckland | Wellington